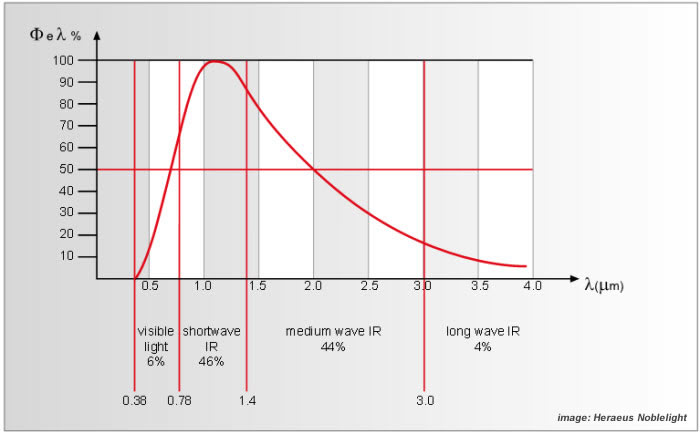

Halogen Infrared heaters emit in the near-infrared region and excel with very high radiation intensity and very fast response time.

They are ideally suited for drying and curing processes where deep penetration and rapid response is required.

Gold coating ensures optimal reflection of infrared heat onto the target surface (95%), thus ensuring high efficiency and significantly reduced heat dissipation towards the rear of the heater. This eliminates the need for additional reflectors to be fitted.

The halogen infrared emitters listed below are standard items which we usually have on stock.

For more information on the full range of infrared emitters, please visit Heraeus Noblelight.

Notes:

Applications

For heating, drying, evaporation, gelling, softening, hardening, tempering, forming, gluing, activating, brazing, laminating, disinfecting, baking of materials latex, foils, paper, carpets, rugs, textiles, plastics, glass, wood, chipboard, insulation board, furniture, fibres, printed circuit boards, car bodies, metals, castings, cores, membranes and shells, leather, foodstuffs. and coatings lacquers, powder coatings, water coatings, primers, finish coats, paints and dyes, printing inks, thin films, glazing, pastes, glues, adhesives.

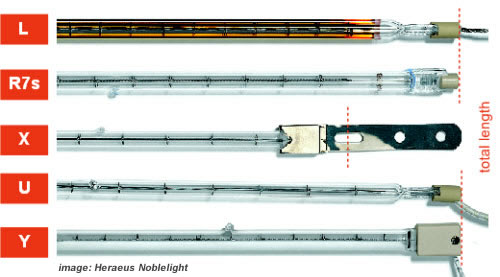

Terminations

The total length of the emitter, for emitter configurations L, R7s, U and Y, is the length between the ends of the complete emitter. For emitter configuration X, the length is the fitting length from the centre of the fitting hole in the metal plate (see diagram). Add to your enquiry list & we will contact you for further specification.

Spectral radiation distribution: