Two-part low to medium temperature resin-based heat transfer compounds for use in moist and corrosive environment, for applications requiring relatively short curing times where steam (heat) is not currently available.

T-802 begins curing upon mixing.

Advantages:

- Nonsoluble in water

- Self-curing —no heat required

- Epoxy resin base creates strong mechanical bond

- Suitable for moist or corrosive environments

T-802 is available in 1-quart (0.946-liter) and -gallon (3.79-liter) cans.

T-802 is a two-part low to medium temperature resin-based heat transfer compound for use in moist and corrosive environments.

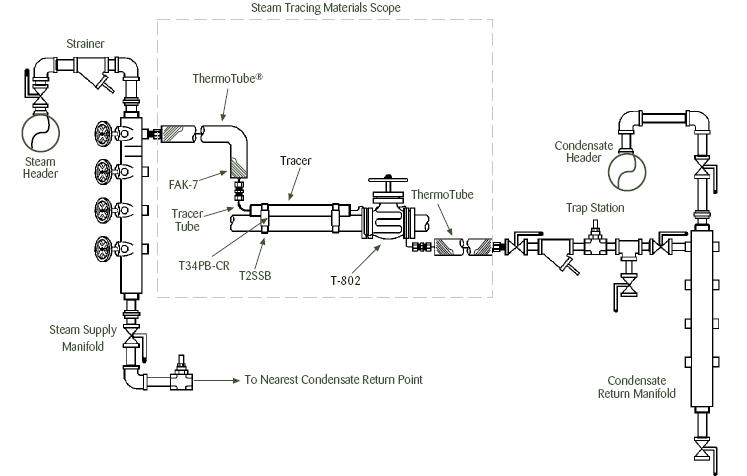

Thermon’s heat transfer compounds provide an efficient thermal connection between the tracer and the process equipment. By eliminating the air voids that would ordinarily exist, heat is directed into the pipe wall primarily through conduction rather than convection and radiation.

A single tracer utilizing Thermon’s heat transfer compound has the equivalent performance of three to five air convection (bare) tracers.

T-802 is typically utilized for applications requiring relatively short curing times where steam is not currently available. T-802 begins curing upon mixing. Curing times vary from 1.25 to 4 hours depending on mixing ratios and ambient temperatures.

Typical installed cross section

Typical steam tracing system using T-802 heat transfer compound

| Container sizes | 1-quart (0.946-liter) cans |

| Maximum exposure temperature | 275°F (135°C) |

| Minimum exposure temperature | -320°F (-196°C) |

| Minimum installation temperature | 32°F (0°C) |

| Heat transfer coefficient, U | tracer to pipe wall 20-40 Btu/hr•°F•ft2 (114-227 w/m2•°C) |

| Electrical resistivity | 146 ohms/inch (57 ohms/cm) |

| Shelf life | 1 year (unmixed) |

| Bond shear | 1,000 lbs/in2 (6,895 kPa) |

| Water-soluble | no |